본문

Manufacturing process

-

01

01Uncoiling

Procedure in which the coil is untied.

-

02

02Slitting

Procedure in which the untied coil is cut into desired size.

-

03

03Skelp

Procedure in which the cut untied coil is rolled.

-

04

04Uncoiling

Procedure in which the skelp is untied.

-

05

05Leveling

Procedure in which the skelp is flatten.

-

06

06Butt Welding

Procedure in which 2 skepls are joined together.

-

07

07Strip Accumulator

Strip Accum ulator eliminates downtime from coil changes.

-

08

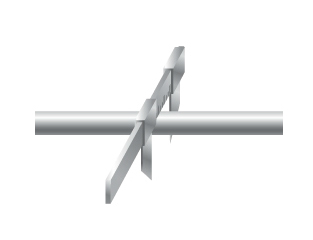

08FF-X Forming

Forming stand for continuously forming a skelp material into a pipe.

-

09

09H.F.Electric Resistance Welding

join sections of pipe.

-

10

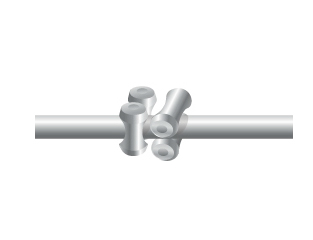

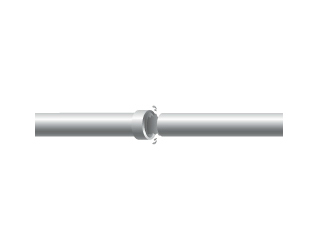

10Eead Trimming

Procedure in which the surplus of welded section is eliminated.

-

11

11Non-Destructive Testing On-Line U.T

Procedure in which the pipe is electromagnetically inspected to detect body wall imperfections.

-

12

12Air&Water Cooling

Procedure in which the pipe is cooled.

-

13

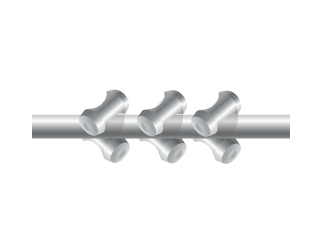

13Sizing

Procedure in which the pipe passes through a series of rolls where it is formed into a true round, and sized to the exact required diameter.

-

14

14Cutting

Procedure in which the pipe is cut into specific length required by customers.

-

15

15Straightening

Procedure in which the pipe is brought to the required straightness.

-

16

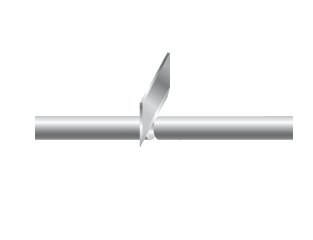

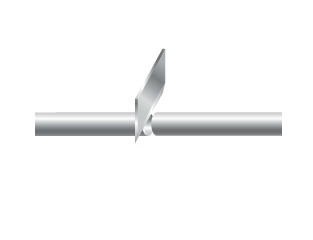

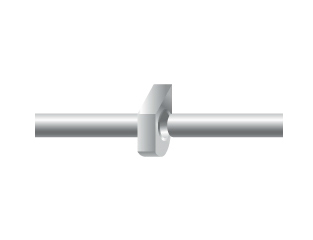

16End Facing

Procedure in which an expanding arbor holds the pipe in line while a revolving head faces and bevels the end of the pipe.

-

17

17Hydrostatic Testing

Procedure in which the finished pipe is visually inspected and is subjected to a hydrostatic test as a strength and leak check before shipping.

-

18

18Marking

Procedure in which the specific information are makred on the pipe.

-

19

19Coating

Procedure in which a coating is applied on the pipe to ensure its durability.

-

20

20Visual & Dimensional check

Procedure in which a final visual inspection is given the pipe prior to stenciling, loading and shipping.

-

21

21Packing

Procedure in which the pipes are packed together with spefic quantity.

-

22

22Shipping

Procedure in which the pipes are delivered to customer.